How ERP Solution Helps Manufacturers Improve Efficiency

In the rapidly growing industrial world, efficiency enhancements are not just for luxurious stuff but are essential for future considerations. With worldwide competition, increasing operational costs, and customer expectations for increased, more precise deliveries, manufacturers are under constant pressure to execute. That is why many manufacturers are looking forward; that is where ERP for manufacturing steps in as a powerful ally. ERP software has become the most vital tool.

ERP solutions for manufacturing and manufacturers are not simply a buzzword but a complete game changer in the industrial era. ERP for manufacturing has redefined how factories operate, manage resources, and scale their operations. In this blog, we will explore in depth how ERP in Manufacturing enhances efficiency for the better and why it is a must-have for every modern production setup and industrial space.

What is ERP for Manufacturing?

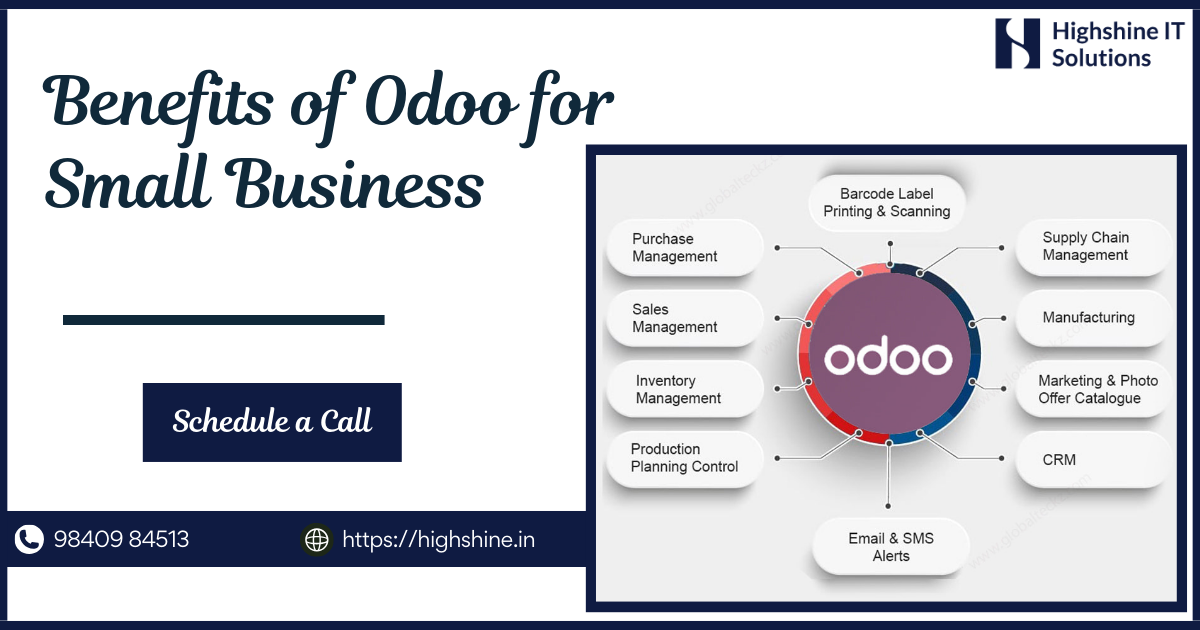

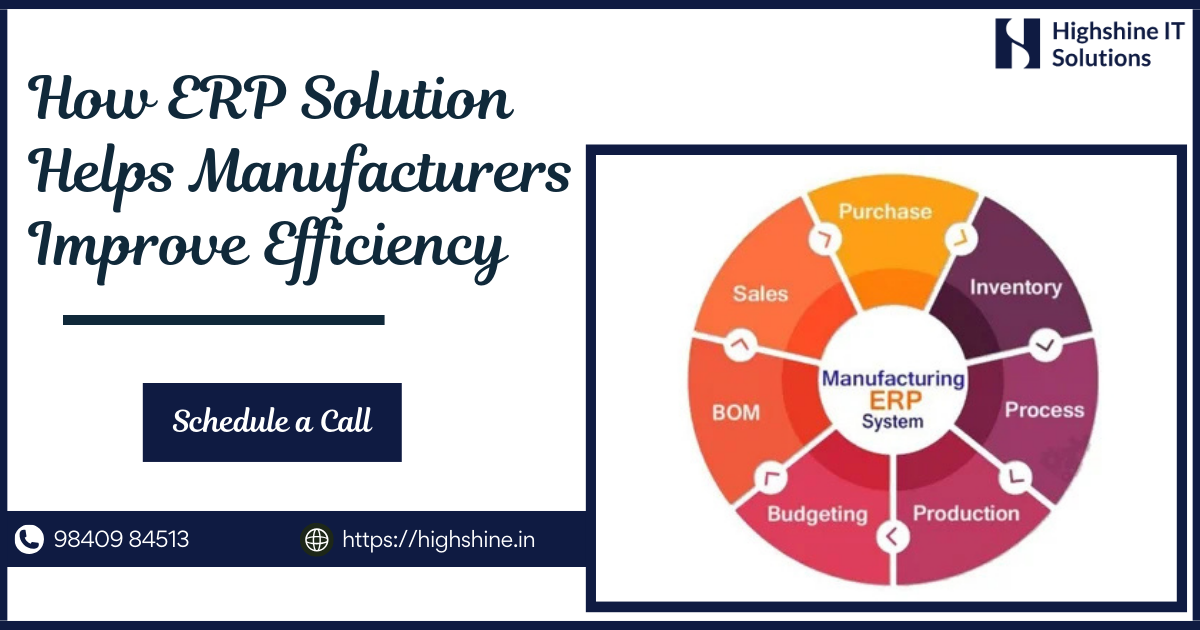

Before delving into how ERP works or how ERP improves efficiency in manufacturing, we should understand what ERP is and how it relates to ERP solutions for manufacturing. ERP stands for Enterprise Resource Planning, a solution that integrates all core business processes into a single unified system. ERP software is a central and professional hub for:

•Raw Material/Inventory Management

•Data and Operations

•Production, Order, and Supply Management

•Equipment Usage and Quality Management

•Sales Management

•Procurement

•HR and Finance

ERP solutions for manufacturing are holistically related to manufacturers and how efficiently they elaborate and uplift their business to the next level with the help of this ERP manufacturing efficiency software. By centralizing data, ERP solutions for manufacturing reduce manual errors and confirm seamless communication between various departments. Additionally, unlike ancient ERP systems, ERP solutions for manufacturing include beneficial modules for production planning, bill of materials (BOM), shop floor control, quality management, and various other things.

Why ERP is Mandatory for Enhancing Manufacturing Efficiency

Generally, manufacturers play a crucial role in operations and executions in complex environments. Meanwhile, efficiency can sometimes be missed or misinterpreted in terms of loss of profitability. Some interpretation factors, like inventory errors, production delays, communication breakdowns, and disconnected data, can uniquely hinder performance. So, overcome the issues where manufacturing efficiency software enters.

ERP solutions in manufacturing help eliminate these inefficiencies by integrating all business functions, automating routine processes, and providing real-time visibility into operations. What is the outcome of using ERP solutions in manufacturing? •Rapid decision-making by using the ERP solutions in manufacturing.

•Finance requires ERP to close the books quickly.

•Sales needs an ERP for manufacturing to maintain every customer's orders and records.

•Reduced redundancies and wastages.

•Well-running ERP solutions for manufacturing to deliver the right products and services to customers through prior logistics.

•Finest supplier and customer relationship management through the ERP for manufacturing to source goods and services through the procurement process.

•Streamlined workflows from the industry floor to the front office.

Some Key Aspects to Understand How the ERP Solutions in Manufacturing Drive More Efficiency

1.Centralized Data Hub for Profitable Decisions

The primary aspect to be considered while understanding how the ERP solutions in manufacturing affect the enhancements and efficiency in the business and industry. This benefit aspect centralised data from many departments into an accessible and single unified system. Data silos, redundancies, and inefficient content are appropriately removed to maintain the high efficiency in every team, like inventory levels, production, sales, procurement, and finance – work from the prior information.

This tends to be beneficial while centralising the data in a unified hub:

•It secures more time and assists in making informed decisions with data at your fingertips.

•By removing the need to work on Google or Excel sheets, ERP solutions for manufacturing reduce the risk of human errors and present data in an easy-to-read format.

2.Streamlined Production Planning and Scheduling

Another essential aspect of using ERP solutions in manufacturing is planning an effective and efficient production timeline and scheduling the ERP for manufacturing. Material shortages and underutilized equipment become recurring problems without extended time durations.

ERP solutions for manufacturing assist in streamlining production and deployment workflows. It provides the ERP solution to plan, maintain, and adjust production workflows.

•This ERP solution for manufacturing predominantly confirms fewer delays and more satisfied customers.

•It is responsible for increasing the efficiency of the planning and scheduling process.

ERP solutions for manufacturing include the latest and most efficient production planning tools that automate the scheduling of production and deployment processes based on customer orders, resource availability, and demand forecasts. By reducing idle time and overproduction, ERP for Manufacturers assists in maintaining a proper and effective production flow, directly enhancing manufacturing efficiency.

3.Improved Inventory and Supply Chain Management

The most mandatory aspect, inventory and supply chain management, is to consider when delivering the expected results when using ERP solutions in manufacturing. The focus must be on tracking inventory levels accurately and setting reorder points while handling the ERP solutions in manufacturing. Some insights to be considered when handling the manufacturing efficiency software:

•It assists you in advancing your supply chain to keep things humming without interruptions.

•Automated reminders ensure inventory stays stocked to avoid production delays.

The misleading and mismanagement of inventory and related things lead to more causes of inefficiency in manufacturing. Overstocking ties up capital, while stockouts can slow production and disappoint customers.

4.Improved Quality Control and Regulatory Compliance

This quality control and management play a vital role in the process of ERP solutions for manufacturing, which can make clients and customers happier and more profitable, meeting high standards. They also have various techniques and strategies to verify and check if rules like ISO and FDA standards are followed correctly. This keeps product quality to standard and promotes the expected result. By spotting and fixing possible problems, manufacturing efficiency software helps cut waste and enhance the quality of the product entirely.

For example, you can set up daily inspections to test the quality of raw materials in a plywood factory.

•This ensures only quality raw materials are moved forward to further processing, rather than avoiding future losses.

•Saves you from violations or penalties by confirming you follow all the regulatory compliances.

•Being compliant with all the regulations helps in producing high-quality products.

•Also, examines the final product's quality to uphold standards.

Meanwhile, a misfocus on quality and management causes heavy losses to the industry and makes a bad impression on the brand’s reputation. ERP solutions for manufacturers include various modules related to quality control and management that confirm the definitive products and services at every stage of production and testing.

5.Better Resource and Cost Allocation

A well-developed ERP solution for manufacturing offers clear insights into how resources like people, machines, and materials are used. This makes identifying underused assets, overworked teams, or outdated machinery easier.

An ERP solution for manufacturing assists you in tracking all expenses from raw materials to production and till delivery. It offers some aspects of resource usage.

•Make data-driven decisions to cut resources and boost efficiency.

•Improve major expenses to increase ROI.

By reallocating resources where they are required most, ERP for manufacturers can execute more efficiently and avoid unnecessary expenses.

6.Real-Time Monitoring of Production Floors

Modern ERP in manufacturing integrates with shop floor equipment via IoT and machine sensors, promoting and involving real-time monitoring of production metrics such as cycle times, downtime, and output rates. Supervisors can rapidly check and find the problems, track KPIs, and adjust processes without waiting for end-of-day reports, increasing continuous improvement through manufacturing efficiency software.

7.Scalability and Flexibility for Growth

As your business develops, the ERP for manufacturing should grow with it. If you are adding new products, expanding to new markets, or ramping up production, a good ERP adapts to the changing needs of your business. Enhance it for future developments.

•No need to regularly update or implement new systems, saving time and money.

•Offers a unified system as manufacturing efficiency software that supports your industry’s growth rather than acting as a blocker.

So, there you have all the benefits, and you can reach high standards by implementing manufacturing ERP software.

Why choose Highshine for an ERP Solution for Manufacturing?

You know the reasons for moving to an ERP solution for manufacturing to improve efficiency; it is time to pick a reputable organisation and choose the right ERP software for implementation!

Highshine IT Solutions meets advanced and state-of-the-art industrial manufacturing requirements and tools. It has been developed and organized by industrial professionals for over a decade. Their expertise in handling and implementing the ERP solutions for manufacturing quickly evolves and is promoted into your workforce, improving swift adoption and increased workflow productivity.

A practical solution like ERP includes all necessary features for managing your business, like finance, sales, supply, customer service, and payroll. As a cloud solution, you benefit from regular upgrades, confirming maximum efficiency with new capabilities and security features. Built-in industry best practices ensure efficient operations at one site or globally, improving customer engagement and supply chain efficiency.

Final Thoughts: The Future of Manufacturing Efficiency Software

In today’s industrial world, both small start-ups and large enterprises need digital transformation and data-driven decision-making. In the evolution process, an ERP solution for manufacturing stands out with a high-profile name. It helps manufacturers advance the processes, lessen costs, and deliver better products faster. ERP in manufacturing lays the groundwork for success. With real-time insights, automation, enhanced collaboration, and compliance, ERP solutions for manufacturing simplify complexity.